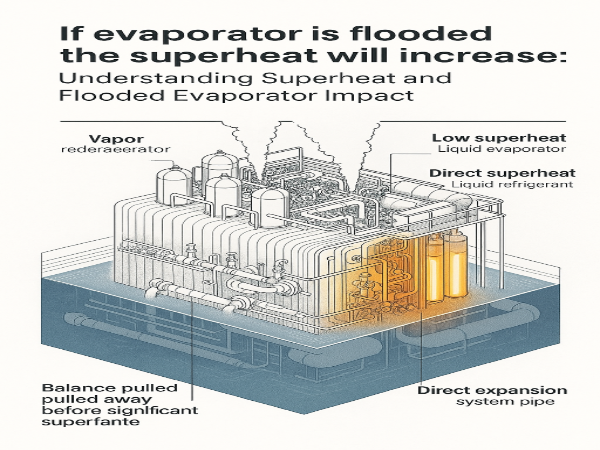

If Evaporator Is Flooded the Superheat Will Increase? Debunking the Myth and Understanding the Real Impact

Discover the true relationship between evaporator flooding and superheat, and how it affects refrigeration system performance, efficiency, and safety.

If the evaporator is flooded, the superheat will not increase—it will decrease. This is a common misconception in refrigeration and HVAC circles. A flooded evaporator means excessive refrigerant is present in the evaporator coil, which prevents the refrigerant from fully vaporizing before reaching the outlet. As a result, the vapor leaving the evaporator remains at or near saturation temperature, leading to low or even zero superheat. Understanding this principle is essential for efficient system design, accurate diagnostics, and preventing compressor damage.

Introduction

In the world of refrigeration and air conditioning systems, the relationship between superheat and evaporator performance is critical to both system efficiency and longevity. However, many professionals and enthusiasts mistakenly believe that if the evaporator is flooded, the superheat will increase. This article aims to clarify this misconception and provide a deep understanding of how superheat behaves under different operating conditions, particularly when the evaporator is flooded.

What Is Superheat?

Superheat is the temperature of a vapor above its boiling point at a given pressure. In refrigeration systems, it is the difference between the actual temperature of the refrigerant vapor leaving the evaporator and the saturation temperature corresponding to the evaporator pressure. It ensures that only vapor enters the compressor, preventing potential mechanical damage.

For example, if the saturation temperature at a given pressure is 40°F and the refrigerant vapor exiting the evaporator is 50°F, the superheat is 10°F. This means the refrigerant has absorbed enough heat to be completely vaporized and then heated an additional 10°F.

Understanding Evaporator Flooding

A flooded evaporator occurs when more liquid refrigerant is present in the evaporator than can be vaporized. This happens due to overfeeding, malfunctioning thermostatic expansion valves (TXVs), or improper system design. In a flooded condition, refrigerant does not fully boil off within the coil and may even reach the compressor in liquid form, risking compressor slugging.

Flooding is often mistaken as a desirable condition for enhanced cooling, but this is misleading. While it may temporarily increase cooling capacity, it significantly compromises system efficiency and safety.

The Myth: Superheat Increases When the Evaporator Is Flooded

One of the most persistent myths in the HVAC and refrigeration field is that flooding an evaporator leads to an increase in superheat. On the surface, it might seem logical: more refrigerant equals more heat absorption, right? Not quite.

In reality, flooding the evaporator results in excess liquid refrigerant remaining at the coil outlet, which keeps the temperature of the leaving vapor very close to the saturation point. As such, the difference between the actual vapor temperature and the saturation temperature shrinks—leading to low or zero superheat.

The Science Behind Superheat Decrease

To understand why superheat decreases during flooding, consider the phase change process. As refrigerant absorbs heat in the evaporator, it undergoes a phase change from liquid to vapor. When the amount of refrigerant exceeds the coil’s ability to vaporize it, some liquid remains. The temperature of this saturated mixture remains constant until all the liquid is vaporized.

Since the outlet vapor is not superheated, and still near its saturation temperature, superheat remains low. In a properly charged and controlled system, only vapor should exit the evaporator—ensuring a stable, measurable superheat value.

Why Low Superheat Is a Problem

Operating with low or zero superheat poses serious risks to the compressor. The compressor is designed to compress vapor, not liquid. If liquid refrigerant enters the compressor, it can cause mechanical damage, oil dilution, and eventual failure—a condition known as slugging.

Moreover, a system with low superheat often exhibits:

- Higher suction pressures

- Reduced overall efficiency

- Increased risk of compressor damage

Maintaining proper superheat is essential for protecting the compressor and ensuring efficient heat transfer in the evaporator.

Diagnosing a Flooded Evaporator

Technicians can identify a flooded evaporator by:

Low Superheat Readings: Near-zero values indicate refrigerant is not being fully vaporized.

Frost or Ice Formation: On suction lines or evaporator outlets.

High Suction Pressure: Due to liquid presence.

Compressor Noise: Indicating liquid slugging.

Proper diagnostics involve measuring both pressure and temperature to calculate superheat accurately. A well-calibrated manifold gauge and temperature probe are essential tools for this task.

How to Prevent Evaporator Flooding

To avoid flooding and ensure optimal superheat levels:

Proper TXV Sizing: The thermostatic expansion valve must match system load and refrigerant type.

Accurate Refrigerant Charging: Follow manufacturer specifications strictly.

Regular Maintenance: Check for clogs, leaks, and valve malfunctions.

Install Suction Line Accumulators: These can trap liquid before it reaches the compressor.

Using a system controller with adaptive algorithms can also help regulate expansion valve operation and prevent flooding conditions.

Superheat and System Efficiency

Maintaining the correct superheat level ensures that the evaporator is utilized effectively while protecting the compressor. A typical superheat value for many systems is between 8°F and 12°F, depending on system design and operating conditions.

Systems operating with low or no superheat (due to flooding) waste potential cooling surface area and risk system instability. On the other hand, systems with excessively high superheat are starved of refrigerant, leading to poor cooling performance.

Real-World Applications and Impacts

In commercial refrigeration systems like walk-in coolers, freezers, and supermarket display cases, maintaining proper superheat ensures product safety and energy efficiency. Flooded evaporators in these contexts not only risk equipment damage but can also compromise stored goods.

In HVAC applications, improper superheat management can lead to customer complaints, increased service calls, and higher operational costs. A well-tuned system balances refrigerant charge and superheat to optimize performance.

Common Misconceptions

Let’s debunk a few widespread myths:

“More refrigerant equals better cooling” – Not true. Overcharging can flood the evaporator and reduce efficiency.

“Superheat increases with flooding” – False. It decreases.

“You can ignore superheat if the system is cold” – Dangerous. Superheat is a critical safety and performance metric.

Understanding the nuances of superheat is not just for engineers; it’s essential for anyone working with refrigeration systems.

Conclusion

The belief that superheat increases when the evaporator is flooded is a technical misunderstanding that can lead to improper system diagnostics and failures. In reality, a flooded evaporator results in low or even zero superheat, putting the compressor and the entire refrigeration cycle at risk.

By understanding the true dynamics between refrigerant flow and superheat, technicians, engineers, and facility managers can make informed decisions to improve system reliability, efficiency, and safety.

Remember: superheat is not just a number on a gauge—it’s a window into the health of your refrigeration system. Keep it in the right range, and your equipment will thank you.