Boosting Heavy-Duty Diesel Output with Parleys Performance Solutions

Setting the Stage for Next-Level Diesel Power

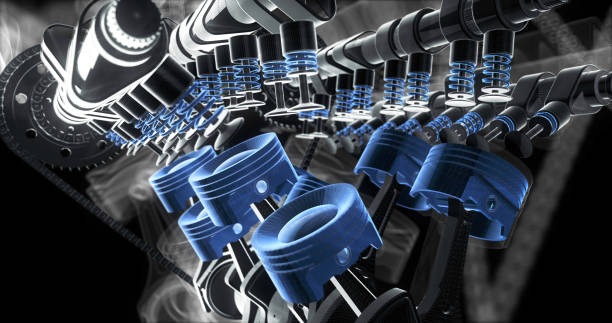

Heavy-duty diesel trucks are no longer just working rigs parked between long hauls. They’re daily operators towing livestock trailers up steep grades, hauling multi-ton loads through mountain passes, and pushing cross-country at sustained high speeds. Stock configurations can meet factory ratings, but pairing mechanical enhancements with precision electronic tuning unlocks untapped muscle. Hardware moves the air and fuel; software tells the engine exactly how to use it. This combination creates sharper throttle response, stronger sustained torque, and the kind of reliability professionals need when peak performance isn’t optional, it’s the baseline.

Upgrading Turbocharging Systems for Maximum Diesel Boost

A properly spec’d high-flow turbocharger can transform a diesel engine from a workhorse into a powerhouse. Larger compressors move more volume while adjustable wastegates fine-tune boost delivery without choking the top end. Select a turbo that’s sized for your specific duty cycle since too large kills low-end torque and too small chokes high-rpm horsepower. Before signing off on a purchase, ask pointed questions: Will this unit hold its efficiency past my intended boost level? Can it spool quickly under load? Is it compatible with existing manifold and downpipe dimensions? The right answers save thousands later.

Strengthening Fuel Delivery with Advanced Diesel Injectors

High-pressure common-rail injectors bring atomization to a razor edge, producing cleaner combustion and more efficient power strokes. Pay attention to spray pattern design since it determines how precisely fuel mixes with air. Flow rate should complement the demands of your turbo output, while material construction must withstand elevated pressures long term. Always match injectors to the fuel pump’s capacity and the capabilities of your chosen ECU tune. Ignore those relationships and you risk leaning out under load or drowning the cylinders when boost peaks.

Software Tuning and ECU Remapping for Diesel Efficiency

Off-the-shelf tunes offer predictable, modest gains but rarely maximize potential. A custom ECU remap tailors parameters specifically to your build’s turbo, injectors, and exhaust flow. Adjusting timing curves, fuel rail pressures, and boost control yields torque that holds across the usable rpm range instead of spiking and falling flat. Reliability testing on a dyno exposes weaknesses before they cost you on the job. Verification of the torque curve isn’t optional for serious operators. It’s proof your investment is paying back exactly where you need it.

Thermal Management in Diesel Engines: Intercoolers and Exhaust

Heat is the silent killer of sustained diesel performance. Larger intercoolers paired with optimized charge-pipe routing keep intake air dense and usable. Avoiding heat soak during extended pulls separates an efficient build from an overheating liability. On the exhaust side, high-flow downpipes reduce backpressure while turbo blankets help regulate turbine housing temperatures. Monitor exhaust gas temps aggressively, not casually. Once heat control slips, so does consistent power under heavy load.

Balancing Diesel Output with Long-Term Engine Durability

Pushing for maximum output requires a strong bottom end, reinforced driveline components, and cooling systems tuned for the added stress. Ignore that and you’ll be rebuilding sooner than you think. Set disciplined maintenance intervals for oil changes, filter swaps, and coolant flushes. Include targeted inspections for wear points like turbo bearings and injector seals. Preventive action is cheaper than pulling an engine that spun a bearing under boosted load.

Estimating Diesel Modification Costs Versus Fuel Savings

Performance upgrades aren’t free, but neither is excessive fuel burn from an inefficient setup. Hardware enhancements like turbos and intercoolers can run into the thousands, while ECU tuning and injector upgrades push the total deeper. Balanced builds often yield measurable fuel savings over the long haul, trimming operating expenses. Running a straightforward payback calculation shows if those savings outweigh upfront costs. Numbers don’t play favorites; they tell you exactly when your investment is worthwhile.

Steering Clear of DIY Diesel Tuning Pitfalls

Most tuning disasters start with mismatched parts and sloppy installs. A turbo without adequate fueling support will starve the engine. Over-boosting without strengthening internals is mechanical roulette. Unverified tunes shove timing curves into unsafe territory. Vet any shop or remote tuner’s previous work. Demand dyno sheets, client references, and evidence they’ve tuned builds similar to yours. Skipping this turns your truck into a test dummy.

Partnering with Professionals for Trusted Diesel Upgrades

Experienced diesel performance shops make power gains stick. They bring controlled testing, precise adjustments, and failure-free install practices to the table. Look for certifications from recognized bodies, on-site dyno capacity, and consistent positive client reviews before committing. Reputable outfits like Parleys diesel performance have proven track records combining hardware upgrades with intelligent tuning to deliver repeatable, safe results.

Accelerating Toward Peak Diesel Performance

Maximizing diesel output lives in the marriage of smart hardware selection, precise fueling strategies, and intelligent software control. Each component shapes the power curve, but together they produce a truck that works harder, lasts longer, and runs colder under strain. Partnering with proven professionals ensures modifications don’t just add numbers to a sheet—they create lasting capability. The road ahead is wide open for those willing to build it right.