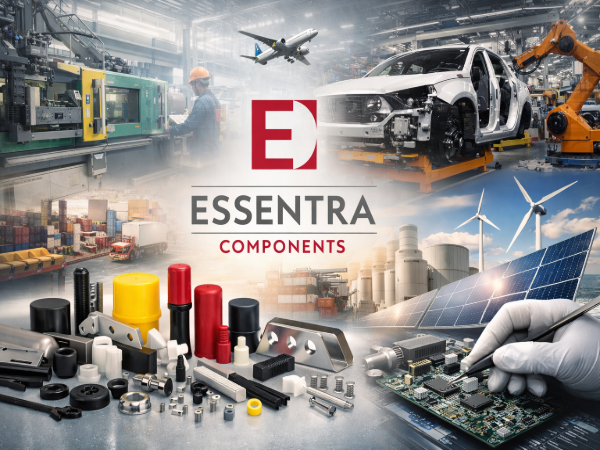

Essentra Components: A Global Leader in Industrial Parts and Solutions

Revolutionizing Manufacturing and Distribution of Plastic, Vinyl, and Metal Components Worldwide

Essentra Components is a global market leader in manufacturing and distributing high-quality plastic injection moulded, vinyl dip moulded, and metal components. Serving industries from automotive to electronics, the company excels in providing standard and customized parts that meet precise engineering requirements. With extensive global reach, advanced manufacturing capabilities, and rapid distribution systems, Essentra Components ensures businesses worldwide can access reliable, durable, and innovative solutions for their production and operational needs.

Introduction

In the modern industrial landscape, the importance of reliable and versatile components cannot be overstated. Essentra Components has emerged as a cornerstone in the global supply of industrial parts, consistently delivering excellence in plastic injection moulded, vinyl dip moulded, and metal components. Their products are crucial in ensuring operational efficiency, quality, and innovation across numerous industries, including automotive, electronics, medical devices, and renewable energy. This article delves deep into the world of Essentra Components, exploring its history, product offerings, technological capabilities, global presence, and role in shaping modern manufacturing.

History and Background of Essentra Components

Founded as a division of the multinational Essentra plc, Essentra Components has grown into a global leader over the decades. The company has leveraged acquisitions, innovative manufacturing processes, and strategic partnerships to expand its reach and capabilities. Essentra Components specializes in essential components that support machinery, electronics, and industrial processes. Its reputation is built on reliability, precision, and the ability to provide both standard catalog items and customized solutions to meet specific client needs.

Over the years, the company has established itself not just as a supplier but as a strategic partner to businesses worldwide, helping them streamline production processes and reduce operational costs. Their focus on quality, innovation, and customer satisfaction has been a driving factor in their global expansion.

Global Presence and Operations

Essentra Components operates in over 28 countries across four continents, including North America, Europe, Asia, and the Middle East. The company has developed an extensive network of manufacturing facilities, distribution centers, and sales offices to ensure quick and reliable delivery to its clients.

Their global footprint allows them to maintain large inventories of components, ensuring that businesses can source parts rapidly without disrupting production. With advanced logistics systems and local support teams, Essentra Components guarantees that clients receive both high-quality components and exceptional service wherever they operate.

The company’s international presence also enables it to understand and cater to regional industrial needs, ensuring compliance with local standards while maintaining global consistency in product quality.

Product Range of Essentra Components

One of the most remarkable aspects of Essentra Components is the breadth and depth of its product catalog. The company offers over tens of thousands of products, spanning multiple industries and applications. Their offerings include:

Plastic Injection Moulded Components

Essentra Components manufactures a wide array of plastic parts using advanced injection moulding technology. These components are used in machinery protection, automotive applications, electronics, and consumer products. Plastic injection moulded components are valued for their durability, precision, and cost-effectiveness.

Vinyl Dip Moulded Components

Vinyl dip moulding allows Essentra Components to produce parts with enhanced grip, insulation, and protective features. These components are widely used in industrial machinery, electrical applications, and equipment handling, ensuring safety and longevity in demanding environments.

Metal Components

Essentra Components also specializes in precision metal parts, including fasteners, hardware, and mounting solutions. These components are engineered to withstand heavy-duty applications, offering strength and reliability for machinery, automotive, and electronic devices.

Protective Components

The company provides caps, plugs, and covers that protect machinery and components during storage, transit, and production. These protective solutions help prevent damage, reduce maintenance costs, and extend equipment lifespan.

Cable Management and Accessories

Essentra Components offers solutions for organizing and securing cables, wires, and tubing, including clips, ties, wraps, and conduits. These products are essential for maintaining clean, safe, and efficient industrial and electrical setups.

Access Hardware

Handles, grips, latches, hinges, and knobs are integral to machinery and industrial applications. Essentra Components provides high-quality access hardware designed to enhance usability and durability.

PCB and Electronics Components

Standoffs, mounts, supports, and other electronics hardware are critical in the design and protection of printed circuit boards. Essentra Components supplies precision parts that facilitate safe and effective electronic assembly.

Custom Solutions

In addition to standard catalog items, Essentra Components offers custom manufacturing services, including prototyping, CAD support, and bespoke part design. This flexibility allows businesses to achieve specialized solutions tailored to their operational needs.

Manufacturing Excellence

Essentra Components’ commitment to quality begins at its manufacturing facilities. Using advanced injection moulding, vinyl dip moulding, and precision metal fabrication, the company ensures every product meets exacting standards. Quality control processes are integrated into every stage of production, from raw material sourcing to final inspection.

Additionally, the company employs sustainable manufacturing practices, including material recycling, energy efficiency, and waste reduction initiatives. These efforts not only benefit the environment but also provide cost-effective solutions for clients.

Technology and Innovation

Innovation is at the core of Essentra Components’ business strategy. The company invests heavily in research and development to enhance product performance, durability, and functionality. Advanced technologies such as 3D CAD design, automated production lines, and precision molding ensure products meet modern industry demands.

The company also embraces digital transformation, offering online product catalogs, technical data sheets, and digital tools to streamline component selection and procurement. By combining innovation with experience, Essentra Components remains at the forefront of industrial component manufacturing.

Industry Applications

Essentra Components serves a diverse range of industries, including:

-

Automotive: Providing durable parts and protective solutions for vehicles and assembly lines.

-

Electronics: Supplying essential hardware and protective components for electronic devices.

-

Medical Devices: Offering precision components for equipment used in healthcare settings.

-

Renewable Energy: Supporting wind, solar, and alternative energy sectors with specialized components.

-

Construction and Agriculture: Delivering reliable solutions for heavy machinery, tools, and equipment.

By catering to multiple sectors, Essentra Components demonstrates its versatility and ability to adapt to complex industrial needs.

Logistics and Distribution

With global distribution centers and advanced inventory management systems, Essentra Components ensures timely delivery of products to clients worldwide. The company’s logistics capabilities allow it to maintain large stocks of essential components, reducing lead times and ensuring production continuity for customers.

Additionally, their commitment to rapid fulfillment and technical support makes them a trusted partner for businesses looking to maintain efficiency and reliability in their supply chains.

Sustainability and Corporate Responsibility

Essentra Components emphasizes sustainable practices across its operations. Initiatives include reducing carbon emissions, minimizing waste, utilizing recycled materials, and promoting eco-friendly manufacturing techniques. By prioritizing sustainability, Essentra Components aligns with global environmental goals while offering clients responsible and efficient component solutions.

Why Choose Essentra Components?

Businesses around the world rely on Essentra Components for several key reasons:

-

Global Reach: Access to components and support anywhere in the world.

-

Extensive Product Range: Over tens of thousands of standard and customizable parts.

-

Quality Assurance: Rigorous testing and manufacturing standards.

-

Innovation: Cutting-edge manufacturing technologies and design support.

-

Customer Support: Technical advice, samples, and bespoke solutions.

-

Sustainability: Eco-friendly practices integrated into operations.

By combining expertise, scale, and innovation, Essentra Components offers unmatched value to industrial clients seeking reliable and versatile component solutions.

Conclusion

Essentra Components stands as a testament to excellence in industrial component manufacturing and distribution. Its global presence, extensive product portfolio, advanced technology, and customer-centric approach make it an indispensable partner for businesses across industries. From plastic injection moulded components to vinyl dip moulded and precision metal parts, Essentra Components continues to shape the future of manufacturing by providing reliable, innovative, and sustainable solutions to meet the evolving needs of modern industry.