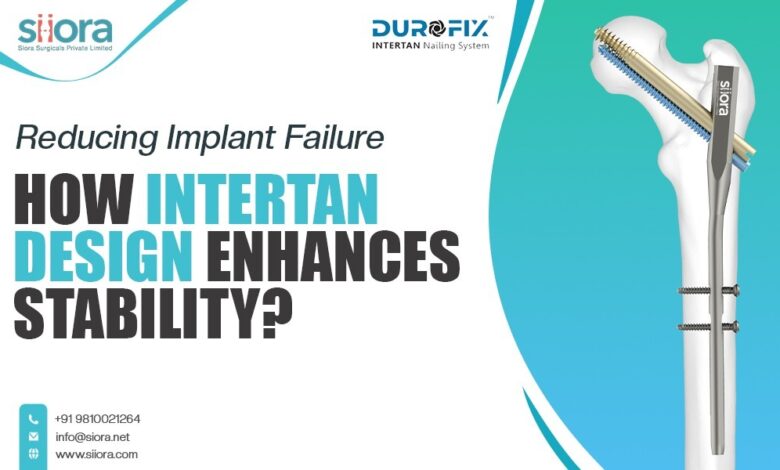

Reducing Implant Failure: How Intertan Design Enhances Stability?

When you break your hip, the last thing you ever want to hear is that the surgery to fix it has failed. The goal is always “one and done.” You want the surgeon to go in, fix the bone, and for that fix to last a lifetime. But implant failure is a real and devastating problem. It means more pain, a longer recovery, and almost always, another major surgery. For years, surgeons battled with implants that just weren’t stable enough for the tricky fractures near the hip joint. Then came the Intertan nail, an implant with a brilliantly simple design that directly attacks the root causes of failure.

The Old Problem: Why Did Implants Fail?

To understand why the Intertan is so good, you have to understand what went wrong with older designs. When a surgeon fixed a hip fracture with a traditional intramedullary nail, they would insert one or two screws through the nail and into the “ball” part of the hip joint (the femoral head) to hold everything together. But these screws often acted independently. This created two huge problems:

- Rotation: Think about a single screw. It’s a circle. It can spin. The femoral head could sometimes rotate around the screw like a propeller. This “rotational instability” is poison for healing.

- Collapse: The forces across the hip joint are massive. Over time, the femoral head could start to collapse downward into what’s called a “varus” position, causing the screws to bend or cut through the bone.

These two issues—rotation and collapse—were the primary culprits behind implant failure. The hardware would loosen, back out, or cut through the weak bone.

The Intertan’s Secret Weapon: The Integrated Dual-Screw Design

The engineers behind the Intertan looked at this problem and came up with a genius solution. Instead of two separate, independent screws, they created a single, integrated construct. The Intertan uses two screws that are locked together as one unit before they are ever inserted. This one change makes all the difference.

By locking the two screws together, they create a solid, rectangular profile inside the bone. Now, think about that. How easy is it to spin a rectangle in a round hole? It’s not. That simple rectangular shape provides incredible rotational stability. The femoral head is locked in place and simply cannot spin. It completely neutralizes the number one cause of instability.

A Rock-Solid Foundation Against Collapse

This integrated, two-screw design does more than just stop the spin. It creates a much broader and more stable platform to support the femoral head. It acts like a powerful internal buttress, resisting the immense downward forces that cause the joint to collapse. It provides a rock-solid foundation that distributes the load more evenly across the bone.

On top of that, the Intertan design allows for what’s called linear compression. The surgeon can squeeze the two ends of the fracture together tightly—a critical step for encouraging the bone to heal—without any risk of introducing that dreaded rotation. It is controlled, stable, and powerful.

What This Means for the Patient: Peace of Mind?

This isn’t just an engineering victory; it has massive real-world benefits for the person recovering from the fracture.

One of the biggest concerns with any fracture surgery is the possibility of needing a second operation. The Intertan implant directly addresses this by tackling the main reasons why previous implants could fail, such as rotation or collapse. This stability is especially beneficial for patients with weaker, osteoporotic bone, where getting a secure grip can be challenging. By providing a more reliable fix in these cases, it dramatically lowers the chance that you’ll need to go through another surgery.

Bottom Line

For a bone to heal correctly, it needs a stable and undisturbed environment. The Intertan nail orthopaedic implant creates just that. Preventing micromovements at the fracture site, allows the bone to mend efficiently. This isn’t just a minor update to an old product; it’s a fundamentally smarter solution based on a deep understanding of biomechanics. It equips surgeons with a more durable and dependable tool, giving them the best possible opportunity to heal right the first time.