Significance of Automotive Sheet Metal Fabrication in Achieving Contoured Vehicles High in Strength and Low in Weight

Automobile manufacturers grapple with finding the balance between meeting cuts on exceeding safety and performance benchmarks and reducing a car’s weight to improve efficiency and provide optimal performance in one streamlined package. One of the approaches to achieving this balance is automotive sheet metal fabrication. This process enables engineers to manufacture structural components of vehicles that require minimal weight to which they add optimal strength. This evolution is made possible by the precision sheet metal fabricator and meticulously devised methods across all segments of transportation.

Whether one is looking for an electric vehicle (EV), a commercial truck, or autonomous systems, the demand for accuracy, flexibility, and uniformity in design is growing. This article delves into modern automotive design in B2B contexts and the relevance of choosing the right fabrication partner, shedding light on the automotive supply chain.

What is the Shift Toward Lightweight Vehicle Design?

Improving fuel efficiency and reducing carbon emissions has automakers prioritizing the reduction of vehicle weight. In the case of electric vehicles, fuel economy translates to weight; and for every 10% reduction, it improves by 6–8%. This is even more critical for electric vehicles because weight reduction translates to an extended driving range and improved battery efficiency.

Reduction in weight has, in the past, relied on material substitution—using aluminum or high-strength steel in place of conventional materials. Today, that approach is complemented by design optimization, which includes precisely engineered sheet metal components devoid of excess material while maintaining the required strength.

The automotive industry has excelled in the ultrathin and lightweight but strong body panels, along with the supporting structural reinforcements and bracket systems. A skilled precision sheet metal fabricator uses CAD-integrated systems and CNC machines to design components that are operationally reliable and can endure varying environmental conditions while meeting stringent tolerances.

What is Balance Strength and Safety?

The reduction of weight is critical; however, it is essential that the safety of the occupants and overall crashworthiness of the vehicle is not compromised. In meeting the stricter modern vehicle requirements for crash test ratings, strategically placed metal components that absorb energy and redirect it with minimal movement are essential.

Automotive sheet metal fabrication makes it possible for engineers to create reinforcements, crumple zones, and roll cages that will satisfy safety requirements for the vehicle. When a high-strength steel is laser-cut and precisely bent, it can offer a perfect combination of flexibility and strength. Today, advanced forming techniques like hydroforming, stamping, and press braking can create unidobe and frame-on-chassis vehicles.

Along with carbon fiber and thermoplastics, other materials are often integrated into hybrid body structures. It is the role of a precision sheet metal fabricator to ensure perfect alignment and accurate hole placement for the sheet metal, while optimizing the overall fit and considering mass production needs.

The Role of Advanced Fabrication Technologies

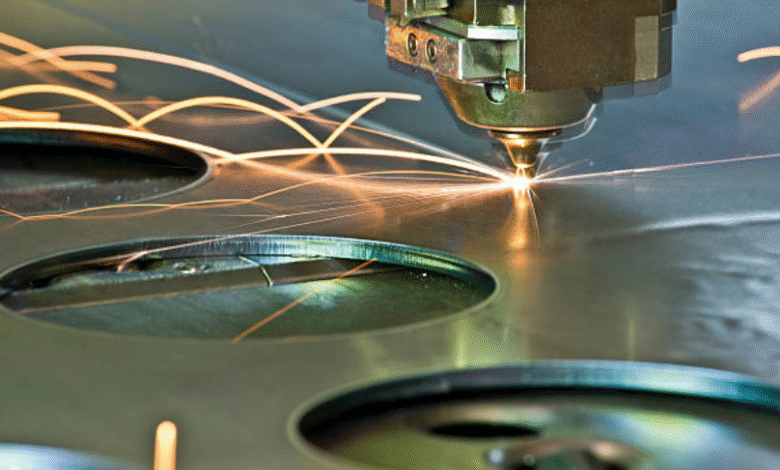

Automotive fabrication has been modernized and now relies on technologies like electric discharge machining, laser cutting, CNC punching, robotic welding, and automated bending. Such technologies transform the fabrication of sheet metal for cars, increasing productivity and maintaining the flawless design of the components.

For automotive applications, various metals like aluminum alloys, stainless steel, and galvanized steel can be used. They can all be rapidly cut using fiber laser cutting systems. The edges that are produced from these lasers are clean with little thermal distortion which further decreases the need for secondary processes.

The robotic bending and welding technologies not only streamline production but also serve to bolster accuracy and efficiency, making them particularly useful for mass production of components such as seat frames, dashboard supports, and battery enclosures. As a rule, the contribution of a professional precision sheet metal fabricator guarantees that tolerances are achieved and quality control measures are compliance checked in each instance.

In this instance, we can say that: Automotive sheet metal fabrication gives the modern precision sheet metal fabricator the capability to manufacture lightweight and durable components for vehicles, while observing the stringent design and safety requirements of the automotive industry.

Customization and Modularity for Next Generation Vehicles

The automotive industry is seeing an increased need for specially designed components as it moves toward electrification and automation. Specialized metal fabrication for battery trays, sensor mounts, and electronic housing parts is necessary to address size, cooling, and EMI shielding specifications.

Facilitating the growing complexity of engineering designed components for electric vehicles, ADAS (Advanced Driver Assistance Systems), and even in-vehicle entertainment modules is made possible with Custom automotive sheet metal fabrication.

The rapid design iteration that precision sheet metal fabricators offer gives them unparalleled utility. The ability to execute design changes, support low- and mid-volume production runs, and uphold precision is critically important for Tier 1 and Tier 2 suppliers to OEMs.

In addition, modular design is gaining importance for vehicles. Subassemblies that can be attached to frames save time and reduce production line expenses. Vehicle systems that utilize sheet metal parts and integrate them must be flawless. B2B customers, whether electric delivery vans or autonomous shuttle makers, appreciate agility and precision from fabricators.

Quality Control, Compliance, and B2B Reliability

In a supply chain, maintaining quality is a requirement for every product. Vehicle suppliers, parts manufacturers, and safety institutions set stringent prerequisites for vehicle parts, and suppliers face them. There is also the need for ISO certifications, PPAP documents, and thorough testing of the materials’ mechanical and dimensional properties.

Precision metal sheet fabricators are a crucial link in the quality chain. A precision sheet metal fabricator will not just supply components, but will also inspect them with CMMs, laser scanners, and material hardness testers. A full compliance and traceability guarantee is then ensured for parts delivered.

A B2B client must be confident that every part’s design will be identical regardless of whether the order is for a hundred or ten thousand units. This is equally crucial for quality. Outstanding performance in these areas helps foster durable collaboration and sustains the just-in-time manufacturing strategies of many OEMs and subcontractors.

Due to increased interests in sustainable practices, leading manufacturers now utilize equipment that minimizes scrap materials, recycles metal waste, and uses energy-efficient equipment. This is aligned with environmental objectives of progressive automotive companies.

Conclusion

Automotive designs are being expedited and innovated due to the need of high performance and tight compliance to eco-friendly measures. In relation to these changes, the fabrication of sheet metals has exuded exceptional importance due to the exceptional lightweight and durable components that support innovation in electric, autonomous, and high-efficiency vehicles.

B2B automotive suppliers are now able to work with precise custom automotive sheet metal fabrication professionals to tap into the engineering knowledge, cutting-edge technology, and rigorous quality assurance frameworks necessary to thrive in the precision automotive industry. Throughout the entire process, custom automotive sheet metal fabrication will provide the foundational structure for the new generation vehicles from initial prototype stages to mass production.

If manufacturers appreciate the role of fabrication engineering in the design, alongside operational aids, there is a significant edge to be gained in competition and the ability to deliver safer and more efficient vehicles to market in less time.