Polyethylene Packaging Solutions Helping Businesses Protect Goods

1. Protection with Advanced Polyethylene Foam

As industries evolve and products become more delicate, the need for dependable and intelligent packaging grows stronger. From precision electronics to heavy automotive parts, businesses today require solutions that not only shield their goods but also optimise efficiency and reduce wastage. This shift has pushed many companies toward Polyethylene packaging solutions, a modern approach known for reliability, flexibility, and long-term performance.

Polyethylene foam packaging is recognised for its balance of strength and lightness. It is engineered using controlled cell structures that distribute impact and resist environmental challenges. This makes it one of the most trusted choices for companies that cannot rely on standard packaging materials. With supply chains operating at high speed, protective packaging must deliver predictable performance every single time—and polyethylene foam rises to that challenge.

2. What Makes Polyethylene Packaging Solutions Different

Every material used for packaging carries its own strengths, but polyethylene foam stands out because it solves several problems at once. Its benefits are not limited to cushioning alone; it offers a complete protective system that businesses can depend on throughout the product’s journey.

Consistency and Repeatable Strength

One of the biggest advantages of Polyethylene Packaging Solutions is consistency. The foam does not weaken after multiple impacts and does not crumble the way some alternatives do. This feature is ideal for multi-use packaging, long-distance deliveries, and factory-to-factory transfers.

Lightweight Without Compromising Protection

Polyethylene is extremely light. As shipping costs continue rising, lightweight materials help businesses reduce transportation fees without risking damage during handling.

Resistant to Moisture and Temperature

Many products today—especially electronics, diagnostic equipment, and temperature-sensitive materials—need protection from changing environments. Polyethylene foam performs well in fluctuating temperatures and does not absorb moisture, ensuring items remain safe even in unpredictable conditions.

Safe for Delicate and High-Value Goods

The foam is gentle against surfaces, making it suitable for polished, coated, or fragile items. It prevents scratching, denting, and vibration damage.

Available in Specialised Grades

Polyethylene foam is manufactured in several types, including anti-static pink for electronic parts, high-density variations for heavy components, and custom thicknesses for specialised applications. Brands like Ethafoam, Stratocell, Jiffycell Polylam, and Nopaplank each offer unique benefits depending on the needs of the product.

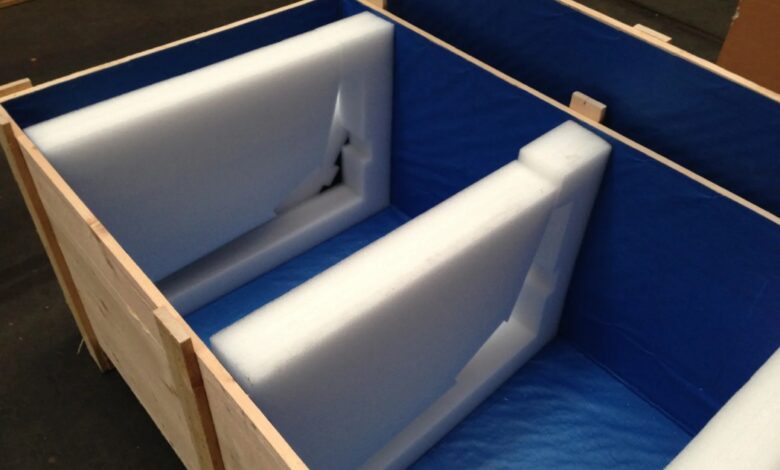

3. A Complete Packaging System Designed Around Each Client

Polyethylene packaging is most effective when combined with a fully structured packaging setup. Many companies today prefer working with specialists who offer a complete solution under one roof. This is especially helpful for businesses that manage large inventories or ship fragile items regularly.

Matching Boxes with Foam Fitments

Outer cartons and internal foam pieces must work together. Packaging experts help select the right box strength, choose the correct fitment design, and test the final structure to ensure the product remains stable during transport.

Reduced Handling and Faster Procurement

Using one supplier for cartons, polyethylene fittings, tape, bubble wrap, and accessories reduces paperwork and simplifies communication. Businesses receive faster responses, avoid stock shortages, and can manage inventory with ease.

Access to Eco-Friendly Alternatives

Sustainability matters more than ever—and polyethylene packaging can be part of an environmentally conscious strategy. Many providers now offer recyclable materials, energy-efficient manufacturing processes, and eco-focused design options that minimise waste without lowering protection levels.

4. Polyethylene Foam as a Versatile, Industry-Ready Material

Polyethylene foam packaging is relied on by a wide range of sectors, making it a key material for protective packaging in the UK and beyond. Its versatility has made it a preferred choice for industries like:

Electronics

Circuit boards, wires, sensors, and devices require controlled cushioning. Anti-static polyethylene foam prevents electrostatic discharge, while its shock-absorbing nature protects sensitive components during transport.

Automotive

From headlights and trim pieces to gear components and precision parts, automotive manufacturers require packaging that withstands weight, vibration, and uneven pressure. Polyethylene foam fitments provide secure housing for irregular shapes.

Furniture

Polished surfaces, fragile corners, and large flat-pack items remain safe with custom foam and corrugated combinations. Polyethylene foam prevents scratches, dents, and friction damage.

Healthcare and Medical Devices

Medical equipment often includes fragile components that cannot be compromised. The foam resists contamination, absorbs impact, and maintains shape, making it ideal for long-distance shipments.

Manufacturing and Tooling

Colour-coded polyethylene inserts help organise toolkits, workshop drawers, and equipment cases, bringing clarity and efficiency to industrial environments.

5. Designing Packaging That Works Harder and Smarter

One of the biggest advantages of Polyethylene Packaging Solutions is the ability to customise the material to match the exact specifications of a product. Protective packaging experts use modern cutting, shaping, and laminating methods to create foam inserts that perfectly cradle an item.

This improves:

- product stability

- stacking efficiency

- warehouse organisation

- brand presentation

- long-term durability

Combining polyethylene foam with corrugated boxes, printed tape, bubble wrap, and bespoke inserts makes the packaging not only protective but professional and visually appealin

6. Benefits of Using Polyethylene Packaging

✔ Long-Term Value

Although polyethylene foam may cost more than polystyrene, its durability makes it cost-effective for repeated use.

✔ Custom Fit for Every Product

Design teams can shape the foam precisely around complex or delicate items.

✔ Superior Shock Absorption

The foam reduces vibration, impact, and pressure, preventing breakage during transport.

✔ Lightweight and Easy to Handle

Staff benefit from easy loading and efficient packing, reducing time and labour costs.

✔ Enhanced Brand Image

Secure packaging shows professionalism and care, strengthening customer trust.

7. Conclusion

As industries strive for greater efficiency, lowered damage rates, and improved sustainability, Polyethylene packaging solutions are emerging as one of the most reliable choices available. They combine strength, adaptability, and design freedom, offering companies a powerful way to protect their products and elevate customer satisfaction. With the right packaging partner, businesses gain not only durable foam fitments but a complete protective system tailored to their operations.

Smart design, high-performance materials, and forward-thinking innovation make Polyethylene Packaging Solutions a key investment for any company that values product safety and brand credibility.