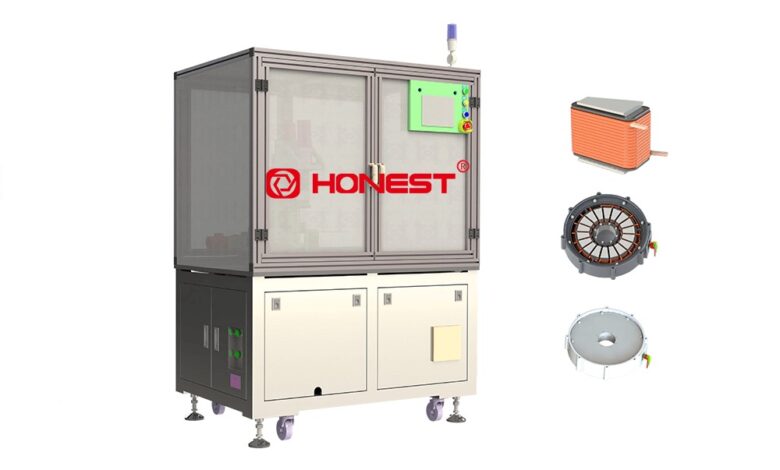

Common Problems in Motor Coil Winding Machines and How to Fix Them

Electric motor winding equipment plays a crucial role in ensuring the efficiency and reliability of motors used across industries. Whether you operate a motor coil winding machine or source solutions from stator winding machine manufacturers, proper maintenance is essential to extend equipment lifespan, reduce downtime, and maintain consistent winding quality. Neglecting upkeep can lead to inaccuracies, frequent breakdowns, and costly repairs. This article explores practical maintenance tips to help you achieve long-term performance and operational stability.

Understanding the Importance of Regular Maintenance

Regular maintenance is not just about fixing problems when they arise; it is about preventing them before they impact production.

Enhancing Equipment Lifespan

Well-maintained winding equipment experiences less wear and tear. Proper lubrication, alignment, and cleaning ensure that mechanical and electrical components function smoothly over time.

Ensuring Consistent Winding Quality

Maintenance helps maintain precision in winding operations. Clean components and calibrated systems reduce defects such as uneven coils or insulation damage.

Reducing Unexpected Downtime

Preventive checks allow operators to identify early signs of failure. Addressing minor issues promptly avoids major breakdowns that halt production.

Daily Maintenance Practices

Simple daily routines can significantly improve the reliability of winding equipment.

Cleaning and Dust Removal

Dust, copper particles, and insulation debris can accumulate on machine surfaces and internal components. These contaminants may interfere with sensors and moving parts.

- Wipe down exposed surfaces daily

- Use compressed air to remove debris from hard-to-reach areas

- Ensure ventilation openings remain clear

Visual Inspection

A quick visual check can reveal potential problems.

- Look for loose wires or connectors

- Check for unusual wear on belts and guides

- Observe for oil leaks or abnormal vibrations

Weekly and Monthly Maintenance Tasks

Beyond daily checks, periodic maintenance ensures deeper inspection and adjustment.

Lubrication of Moving Parts

Proper lubrication reduces friction and overheating.

- Follow manufacturer-recommended lubrication schedules

- Avoid over-lubrication, which can attract dust

- Use appropriate lubricants for different components

Checking Electrical Connections

Loose or corroded connections can cause inconsistent performance.

- Tighten terminals and connectors

- Inspect insulation for cracks or discoloration

- Verify grounding systems are intact

Calibration and Alignment

Over time, mechanical alignment may drift, affecting winding accuracy.

- Check tensioning systems

- Verify guide alignment

- Recalibrate sensors and control systems as needed

Maintaining Mechanical Components

Mechanical systems are the backbone of winding equipment and require special attention.

Monitoring Bearings and Shafts

Bearings support rotating components and are prone to wear.

- Listen for unusual noises

- Check for excessive heat

- Replace worn bearings promptly to prevent further damage

Inspecting Belts and Drive Systems

Belts and drives transmit motion throughout the machine.

- Look for cracks, fraying, or slack

- Maintain proper tension

- Replace components showing signs of fatigue

Electrical System Care

Electrical components are sensitive and critical to safe operation.

Preventing Overheating

Excessive heat shortens the life of motors and control units.

- Ensure cooling systems are functional

- Keep vents and fans clean

- Monitor temperature readings regularly

Protecting Control Panels

Control panels house vital electronics.

- Keep panels sealed to prevent dust ingress

- Avoid exposure to moisture

- Periodically test emergency stops and safety interlocks

Operator Training and Best Practices

Even the best equipment can fail without skilled operation.

Training Operators

Well-trained operators can identify issues early.

- Teach proper startup and shutdown procedures

- Emphasize correct material handling

- Encourage reporting of unusual sounds or behavior

Avoiding Overloading

Operating equipment beyond its capacity accelerates wear.

- Follow recommended operating parameters

- Use appropriate wire sizes and materials

- Avoid continuous operation without scheduled breaks

Record Keeping and Maintenance Scheduling

Documentation is a powerful maintenance tool.

Maintaining Service Logs

Detailed records help track equipment health.

- Log inspections, repairs, and part replacements

- Note recurring issues

- Use records to plan future upgrades

Implementing Preventive Maintenance Schedules

A structured schedule ensures consistency.

- Assign daily, weekly, and monthly tasks

- Review schedules periodically

- Adjust based on equipment usage and environment

Environmental Considerations

The operating environment directly affects equipment longevity.

Controlling Temperature and Humidity

Extreme conditions accelerate degradation.

- Maintain stable room temperature

- Control humidity to prevent corrosion

- Use protective enclosures if necessary

Ensuring Clean Workspaces

A clean environment reduces contamination risks.

- Organize tools and materials

- Limit airborne dust

- Implement regular housekeeping routines

Knowing When to Seek Professional Support

Some maintenance tasks require expert assistance.

Periodic Professional Inspections

External inspections provide an objective assessment.

- Identify hidden issues

- Receive expert recommendations

- Ensure compliance with safety standards

Timely Component Replacement

Delaying replacement can cause cascading failures.

- Use quality spare parts

- Replace aging components proactively

- Plan downtime strategically

Conclusion

Long-lasting performance of electric motor winding equipment depends on a balanced approach to maintenance that combines daily care, periodic inspections, skilled operation, and proper environmental control. By implementing these best practices, facilities can maximize efficiency, minimize downtime, and protect their investment. Whether maintaining a motor coil winding machine or evaluating solutions offered by stator winding machine manufacturers, a proactive maintenance strategy ensures reliable operation and sustained productivity for years to come.